Stand Up To All Types of Pressure

Stand Up To All Types of Pressure

Since 1947, Swagelok has engineered, developed, and manufactured high-quality fluid system products to meet the growing requirements of industry. Our focus is on understanding our customers’ needs, finding timely solutions, and adding value with our products and services.

Today, industrial fluid system applications demand more. Higher pressure and temperature design standards require higher integrity products that can withstand even the most unwilling environments and unrelenting elements. Swagelok’s IPT Series Cone & Thread fittings ensure safe, reliable, efficient, leak-tight operations up to pressures of 60,000 psig every day, every hour, without exception.

A Closer Look

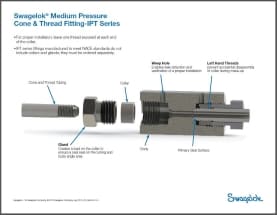

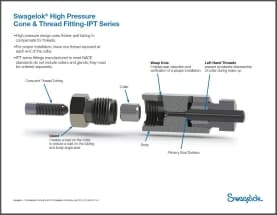

Swagelok’s IPT fittings come in two variants: the medium pressure fittings are designed for working pressures up to 20,000 psig (1378 bar) and the high pressure fittings for working pressures up to 60,000 psig (4134 bar). Both variants are available in a variety of sizes with a standard material of construction of 316 cold-worked stainless steel, required for higher yields in tensile strength for higher pressure applications.

Click on each of the thumbnails above for a larger image

Coned and threaded fittings have three basic components: the gland, collar and body. These components work in tandem with coned and threaded tubing to create a leak-tight seal. Tubing is coned at a 59-degree angle which mates with the 60-degree sealing surface of the seat within the fitting body. The collar threads onto the coned and threaded tubing with left-hand threads to prevent accidental disassembly of the collar during installation. This assembly is then installed with the gland which creates a load on the collar to ensure a seal on the tubing and body angle. While both the medium- and high-pressure fittings share the same basic design, the components of each are not interchangeable.

Performance in Demanding Applications

From wellheads to refineries, upstream or downstream, shorten your supply chain and simplify your day. Find all the right connections for your medium- and high-pressure applications with Swagelok. We know that options help keep projects on time and on budget which is why we offer a growing selection of 7,000+ standard medium- and high pressure configurations to simplify your build schedule and control costs. When you’re under pressure, go above – our IPT download has more information on the different types of fitting configurations and ordering information.