Are You Compromising Safety with Poor Tubing Quality? | Article Index | Blog - Weekly Column | Resources

Quality control starts with selecting a qualified tubing supplier, performing an assessment, and approving the supplier based off your requirements and customer's requirements. Depending on the supplier, they will have quality control procedures of their own to ensure that quality product is being delivered as promised.

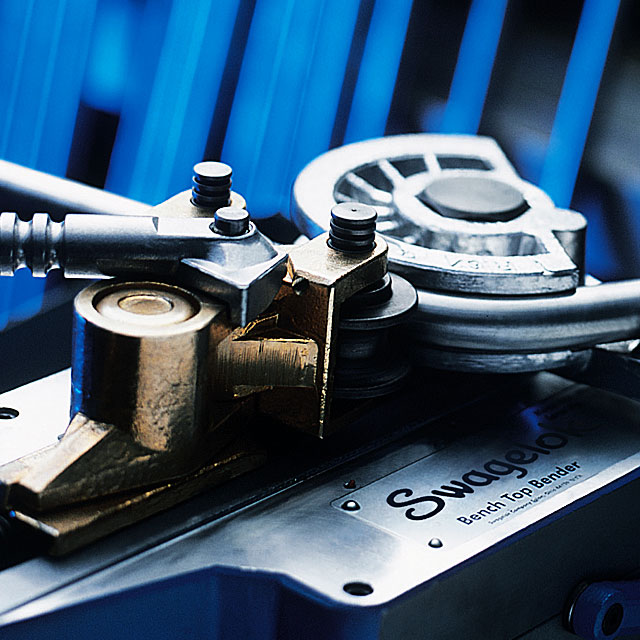

If you're considering a change in tubing suppliers, or looking to specify a low-cost alternative, there's more to consider than just cost. Swagelok Calgary | Vancouver | Red Deer | Medicine Hat | Prince George is committed to providing high quality product that doesn't compromise safety, fluid system performance, and increase your cost of MRO (Maintenance, repair and operations).

3 Key Area's Poor Tubing Quality Can Affect:

System Performance |

Safety |

Cost |

|

|

|

| Poor Quality = Poor Performance |

Poor Performance = High Safety Risk |

High Safety Risk = Increased Labor Cost |

Assess Your Current Tubing Supplier

If you're using high quality tubing, you should be able to answer YES to the following:

- Does your tubing bend seamlessly and consistently

- Does your tubing install into a tube fitting properly?

- Does your tubing have complete traceability to the MTR?

- Does your tubing tolerance match your tube fitting tolerance?

Whether it's supplying high quality tubing, or providing Evaluation & Advisory Services to help improve your operations, Swagelok can help.