CNC Tube Bending

Enhanced CNC Tube Bending Capability

Repeatable and scalable, our CNC tube bender complements our expanding assembly and fabrication services offering. With the capability to produce both simple and complex, multi-axis bends with incredible accuracy, the Unison Breeze machine is faster and more precise, while simultaneously decreasing waste and rework, than traditional hand tube bending.

Ideal CNC Applications

Whichever way you look at it, the biggest advantage of the CNC tube bender is repeatability. But here are some other applications to consider:

- High volume, project based bending

- Batched, repeatable bends to complement production scheduling

- One-off, specialty tube bends

- Complex, multi-axis bends and extended tubing runs

- Tubing bends that must meet rigid tolerances

No Drawing, No Problem

Often, we’ll have customers come into the shop with a piece of bent tubing that they need to replicate. Traditionally, we’d inspect the tubing, take measurements, prepare tooling, cut the tubing to length, execute the bend and review measurements and tolerances against the original.

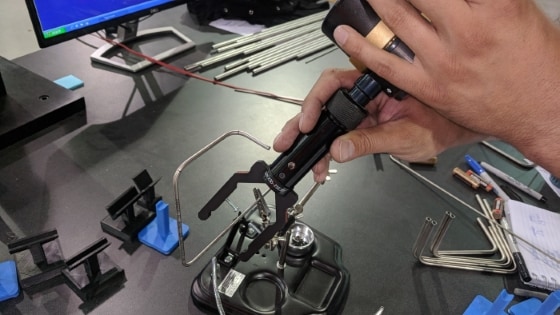

With our coordinate measuring machine (CMM) arm, we’re able to measure and capture the physical, geometrical characteristics of the existing bent tubing. The CMM then produces the coordinates for the precise replica and communicates with the CNC tube bender. The process is seamless, worry-free, and reduces the opportunity for human error. The finished product is the exact identical to the tightest tolerance with no prototyping, waste or re-work.

Our automated CNC tube bending and CMM capability can help streamline your production requirements and bring new efficiencies to your operations by controlling variable labour costs, decreasing the number of connection and potential leak points, and taking advantage of economies of scale.

Ready to Get Started?

Send us your drawing for quote or visit our facility for a thorough demonstration of this robust technology.